by Tom Cucuzza – The Sourdough Journey (c) January 2023

Why do some sourdough recipes call for a 30% rise and others a 100% rise?

One of the great mysteries of sourdough baking is why some recipes recommend a 30% rise and others recommend up to a 100% rise during bulk fermentation. Both methods produce very similar results. How is this possible?

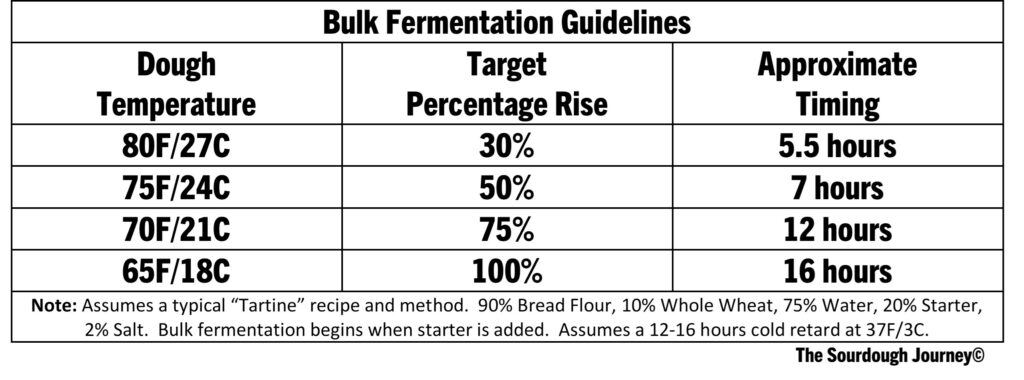

The difference is due to the dough temperature during bulk fermentation. I have reviewed and tested dozens of recipes and there is a clear correlation between the target bulk rise, and the bulk fermentation dough temperature. Recipes calling for a warm bulk fermentation temperature (e.g., Tartine at 80F/27C) recommend a low percentage rise (30%), while recipes calling for a cool bulk fermentation temperature (70F/21C) recommend a higher percentage rise (75-100%).

The reason is because the dough keeps fermenting in all of the downstream steps after bulk fermentation, until the loaf is baked. Consequently, warm-fermenting dough needs to be cut off earlier in bulk fermentation than cool-fermenting dough. With warm-fermenting dough, you need to “hit the brakes” at a lower percentage rise to prevent the dough from overproofing in the shaping and final proofing steps. It takes a long time for warm dough to cool down.

Different Dough Temperatures Require a Different Percentage Rise in Bulk Fermentation

Different dough temperatures require a different percentage rise to achieve equal fermentation at baking time.

Measuring the dough temperature and percentage rise is the most accurate and repeatable method of determining the end of bulk fermentation. But, the dough temperature and percentage rise are inextricably linked. A 100% rise at 70F/21C produces a much different result than a 100% rise at 80F/27C. The percentage rise alone is a meaningless data point without also knowing the dough temperature.

The approximate timing is provided here as a reference, but it is a weak predictor of when bulk fermentation should be cut off. The percentage rise does not lie! You can bulk ferment at any dough temperature, but the combination of dough temperature and percentage rise are the secret to perfect, predictable, and repeatable sourdough fermentation. But you must measure both.

Everyone’s starters and flours are different so your results may differ from these guidelines. If you overproof your dough at these recommended targets, then the next time you bake, reduce your target rise by 10%. If you underproof, then increase the target rise by 10%. By carefully measuring and keeping records of your dough temperature and the percentage rise, you can dial in the optimal target rise within a few bakes. Once you find the right percentage rise for a specific dough temperature, it never changes for that recipe.

Continue reading for more important details and examples!

PART 1: UNDERSTANDING THE INTERPLAY OF DOUGH TEMPERATURE AND PERCENTAGE RISE

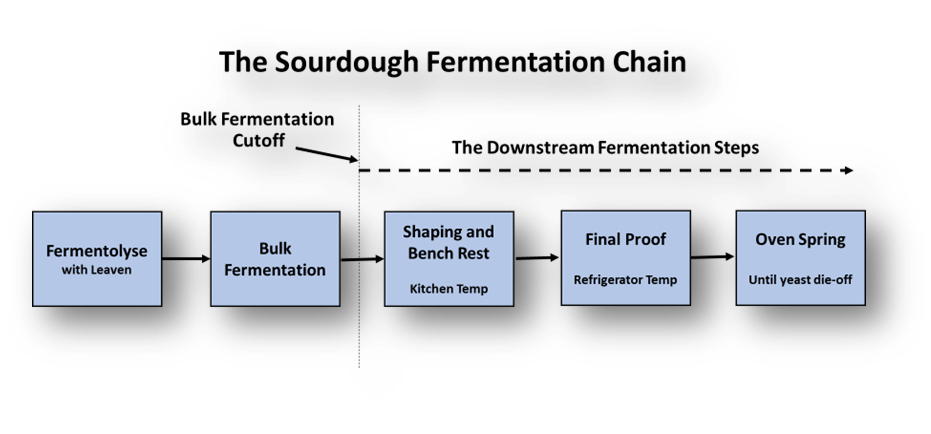

To best understand the importance of properly cutting off bulk fermentation, one must consider the entire fermentation chain.

The “end” of bulk fermentation is the “beginning” of the downstream steps in bulk fermentation. The dough temperature and percentage rise at the end of bulk fermentation determine how the dough behaves throughout the remaining steps until it is baked.

The Setup for the Fermentation After “Bulk Fermentation”

When bakers decide to cut off bulk fermentation, they may believe that somehow the dough hears that message and stops fermenting. It does not. In fact, the dough keeps fermenting at the same or faster rate until the dough temperature cools down to refrigerator temperature (37F/3C) which can take 8-12 hours! Note: This example assumes a cold retard in the refrigerator after shaping, but the same principles apply with countertop proofing at room temperature.

The end of bulk fermentation is the beginning of the fermentation “glide path” from shaping until the yeast die-off point during baking. Your decisions and actions at the end of bulk fermentation determine how all the remaining steps will play out.

The Downstream Fermentation Steps

When a baker cuts off bulk fermentation, this is an arbitrary cutoff point we create in our minds, but the dough keeps fermenting!

· During the 40 minutes of pre-shaping, bench rest and final shaping, the dough keeps rapidly fermenting. Warm dough (80F/27C) can increase in volume by at least 10% during this time. You don’t see this rise because you are handling and shaping the dough, but it is rapidly fermenting. The dough temperature at the time of shaping determines how rapidly the dough will ferment during this 40-minute period.

· When you place your shaped dough in the refrigerator for a cold retard, it can take 8-12 hours for the dough to reach “hibernation” temperature of 37F/3C. During that long cooldown, the dough continues to ferment, particularly in the first few hours when the dough is still above 50F/10C. The dough temperature, when it enters the refrigerator, determines how fast and how much the dough will continue to ferment throughout the cold retard.

· Lastly, as the dough warms up again in the oven during the initial phase of baking, the fermentation process reactivates until the dough temperature reaches the yeast die-off point of 130F/54C during baking in the oven. Experienced bakers always pace their fermentation to leave a little “gas in the tank” for the final burst of fermentation in the oven. We will focus primarily on what happens during shaping and the cold retard. See Appendix 1: What Happens in the Oven During Baking? for more information on that topic.

The End Point – The Perfectly Fermented Loaf

Every baker’s goal is to have every loaf end up in the same place – a perfect, fully fermented loaf. You can bulk ferment at a wide range of temperatures, but you need to synchronize your bulk fermentation percentage rise with your dough temperature for optimal results.

The key is understanding how your actions at the end of bulk fermentation influence all of the downstream fermentation steps.

PART 2: DOUGH TEMPERATURE DETERMINES THE FERMENTATION SPEED

As you approach the end of bulk fermentation, you want to focus on two questions:

1) How much has the dough risen? Your dough readily shows how much it is fermenting by the rise in the dough. The percentage rise determines how far along the dough is in the fermentation process.

2) What is the dough temperature? Sourdough fermentation is a highly temperature-sensitive, biological process. Warm dough ferments much faster than cool dough. The dough temperature determines the fermentation speed.

Warm Dough (80F/27C) in the Downstream Steps

If you are following the Tartine method, for example, and bulk fermenting your dough at 80F/27C dough temperature to a 30% target rise in the dough, consider what happens after the end of bulk fermentation. After bulk fermentation, the dough spends 40 minutes at room temperature during the shaping steps. During this time the dough is continuing to rapidly ferment, and the yeast population is rapidly reproducing.

You do not typically see this rise during shaping because you are handling, shaping and de-gassing the dough – but it is happening. If your dough remained unshaped for 40 minutes after the end of bulk fermentation you would see it rise at least 10%, sometimes more. So, a 30% rise at the end of bulk fermentation continues to at least a 40% rise before the dough goes into the refrigerator.

After shaping, the warm, shaped dough goes into the refrigerator for the cold retard at a dough temperature of approximately 78F/26.5C (warm dough loses a few degrees of temperature during the shaping process). Many people mistakenly believe that the dough immediately approaches refrigerator temperature once it goes into the refrigerator. It does not. The dough takes a long time to get down to refrigerator temperature – as long as 12 hours to reach a dough temperature of 37F/3C. During this time the dough keeps fermenting.

Cool Dough (70F/21C) in the Downstream Steps

If you are following a recipe that calls for cool bulk fermentation at 70F/21C (or lower), these recipes often call for a 75% (or higher) rise at the end of bulk fermentation. Let’s assume 75% in this example. The difference between 70F/21C and 80F/27C may not seem like a lot, but the fermentation rate at 70F/21C is about 50% slower than the fermentation rate at 80F/27C. In other words, warmer dough is fermenting and rising almost twice as fast as cooler dough. Let’s call this the fermentation speed. During the 40-minute shaping and bench rest, 70F/21C dough will rise only about 5% in volume, or half the fermentation speed of the 80F/27C dough.

Warm dough rises at approximately 20% per hour and cool dough rises at approximately 10% per hour as each dough reaches the end of bulk fermentation.

PART 3: THE IMPACT OF FERMENTATION SPEED ON DOWNSTREAM STEPS

Because warm dough is fermenting faster than the cool dough, we need to “hit the brakes” earlier with warm dough versus cool dough. The warm dough takes much longer to slow down its rapid fermentation rate as the dough cools in the refrigerator.

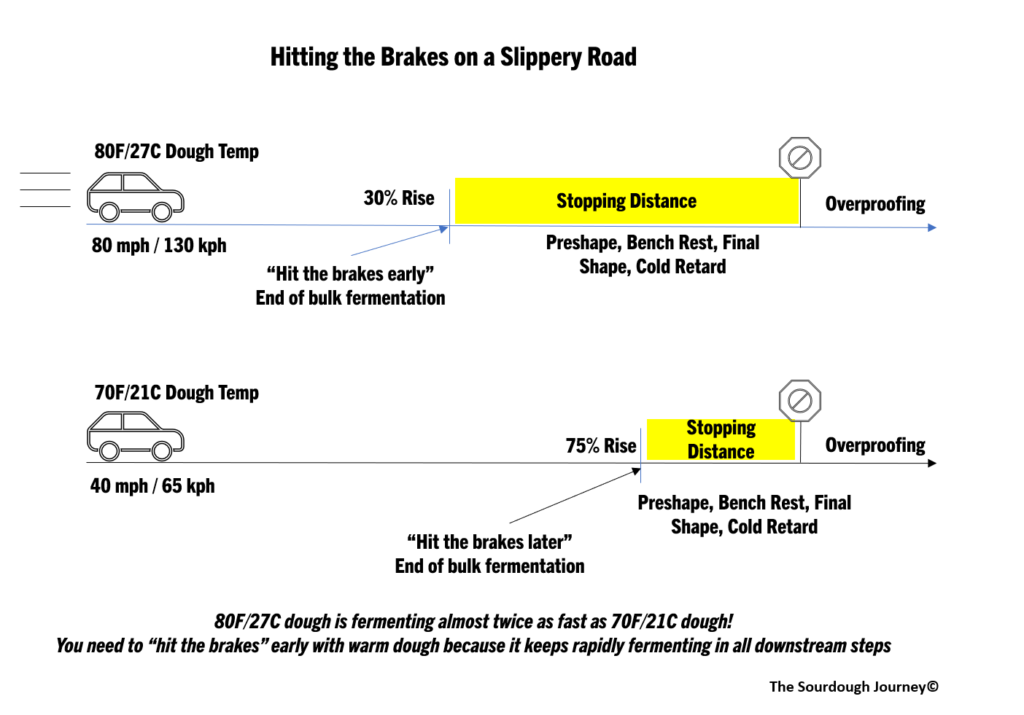

An Example: “Hitting the Brakes on a Slippery Road”

If you were driving your car on a slippery road and you saw an upcoming stop sign, you need to assess your distance to the stop sign (i.e., how much more the dough needs to rise to be fully fermented), and your speed (i.e., how fast is the dough fermenting) to determine when to hit the brakes.

If you are traveling at 80 mph / 130 kph, you need to hit the brakes much earlier than if you are traveling at 40 mph / 65 kph. That speed difference is the equivalent of the difference in fermentation speed between 80F/27C and 70F/21C. Warm dough is fermenting almost twice as fast as cool dough – so, you need to hit the brakes earlier with warmer dough.

“Hitting the brakes earlier” means cutting off bulk fermentation at a lower percentage rise (e.g., 30%) because the dough is rapidly fermenting and it keeps fermenting in all of the downstream steps. At faster speeds, you need a longer stopping distance to avoid skidding through the stop sign – which would result in an over-proofed loaf.

PART 4: WHAT HAPPENS IN THE REFRIGERATOR DURING A COLD RETARD?

Once your shaped dough is placed in the refrigerator for a cold retard, the warm dough and cool dough continue to behave differently, and to complicate matters, cooling dough does not “show the rise” as visibly as bulk fermenting dough.

Warm Dough (80F/27C) in the Refrigerator

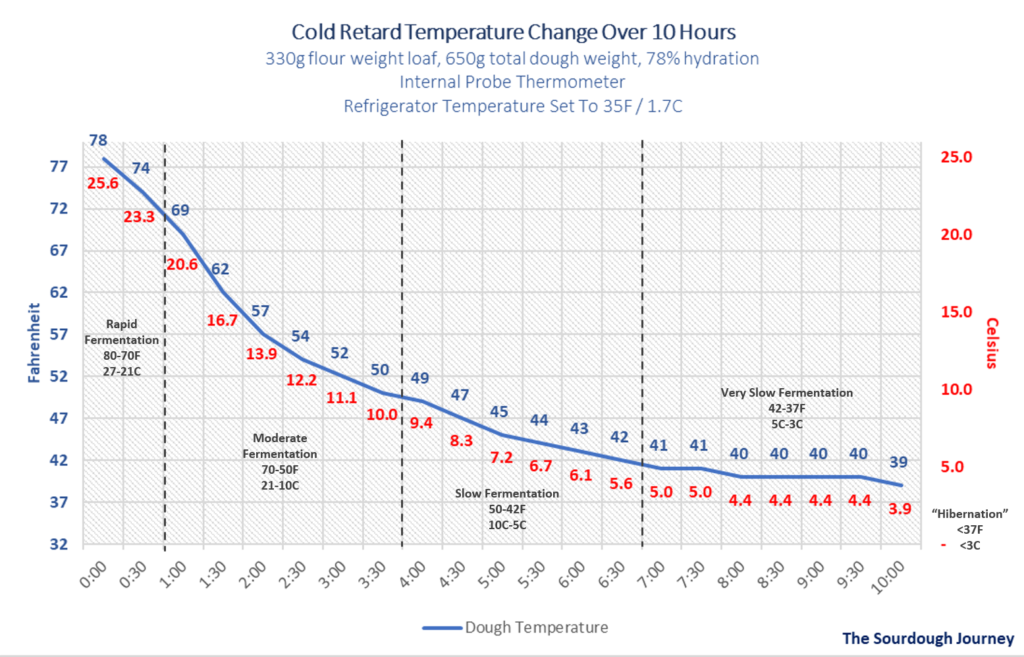

When you place warm dough in the refrigerator for a cold retard, the dough keeps fermenting until the internal dough temperature reaches about 37F/3C. This can take up to 12 hours. Prior to that time, the dough keeps fermenting as the dough slowly cools through different temperature ranges. The following chart shows the cooling dough temperature in the refrigerator for dough that ended bulk fermentation at 80F/27C.

How Does Warm Dough (80F/27C) Behave in the Refrigerator?

Phase 1: 80F-70F / 27C-21C Dough Temperature in the Refrigerator – Rapid Fermentation

It takes about 60 minutes for warm dough to cool down from 80F to 70F / 27C to 21C in the refrigerator. During this time, the dough doesn’t know it is in the refrigerator. It keeps fermenting at the same pace as if it were on the countertop at room temperature. In this 60-minute time period, warm dough can continue to rise as much as 20%.

You don’t see the rise as readily in the refrigerator because the dough was recently compressed during shaping, and the gasses in the dough begin shrinking as the dough cools down. Have you ever put a balloon in the refrigerator? It shrinks. The dough is shrinking as it cools, but it also expanding as it ferments. The visible rise in the refrigerator is not exactly indicative of how much the dough is continuing to ferment, but I have done experiments on unshaped dough throughout the cold retard process to approximate the percentage rise that occurs in the refrigerator.

Phase 2: 70F-50F / 21C-10C Dough Temperature in the Refrigerator – Moderate Fermentation

As the dough cools/ down from 70F to 50F / 21C to 10C, the dough keeps fermenting, but now at a pace slower than typical bulk fermentation speeds (due to the lower dough temperature). It takes approximately 3 hours for the dough temperature to travel through this temperature range, and the dough continues rising approximately 10-20%. It is difficult to see and measure this rise in a shaped loaf, but it is fermenting.

Phase 3: 50F-42F / 10C-5C Dough Temperature in the Refrigerator – Slow Fermentation

Once the dough reaches 50F/10C, the fermentation activity significantly slows down and it takes approximately 3 hours for the dough to travel through this temperature range. There is generally no visible rise in the dough during this 3-hour period, but it is continuing to slowly ferment. If your dough remains in this range (above 42F/5C) for more than 12 hours, it will likely overproof. This occasionally occurs in the summer when refrigerator temperatures may be as high as 45F/7C.

Phase 4: 42F-37F / 5F-3C Dough Temperature in the Refrigerator – Very Slow Fermentation

Depending on your refrigerator temperature, the dough takes another 6-8 hours to reach /37F/3C. The dough continues to rise and ferment very slowly during this phase. If you are trying to build more sour flavor in your loaves, this is a good temperature range for longer fermentations.

Phase 5: 37F/3C Dough Temperature in the Refrigerator – “Hibernation”

When the dough reaches 37F/3C, it is generally considered to be at the “hibernation” temperature. The dough keeps fermenting, but extremely slowly. You can keep your dough in the refrigerator for days at this temperature. 24 hours in the refrigerator at 37F/3C is the equivalent of 30 minutes (maximum) of peak bulk fermentation time. Days at 37F/3C are the equivalent of minutes of fermentation at 80F/27C.

How Does Cooler Dough (70F/21C) Behave in the Refrigerator?

When you load cool dough into the refrigerator, it behaves differently than warm dough, especially in the first 6-8 hours.

Phase 1: 80F-70F / 27C-21C Dough Temperature in the Refrigerator – Rapid Fermentation

Because the dough enters the refrigerator at 70F/21C, there is no rapid fermentation phase at warm temperature. This is a major difference between 80F/27C dough and 70F/21C dough in the refrigerator. Warm dough rapidly rises approximately 20% during the first hour in the refrigerator. Cool dough bypasses this phase.

Phase 2: 70F-50F / 21C-10C Dough Temperature in the Refrigerator – Moderate Fermentation

Cool dough enters the refrigerator at about 70F/21C, but it behaves differently than the warm-fermented dough at the same temperature. Warmer-fermented dough typically has a larger, more active yeast population so it more vigorously ferments in this range. The optimal temperature for yeast production and re-production is 75-80F / 25-27C. The cool dough never hits this temperature range during bulk fermentation, so it never reaches its peak production or reproduction rate.

Phases 3-5: 50F-37F / 10C-3C Dough Temperature in the Refrigerator – Slow, Very Slow, Hibernation

By the time the 70F/27 dough cools down to 50F/10C, it generally follows the same trajectory as the warmer dough down to 37F/3C. In this range, the fermentation rates are fairly similar.

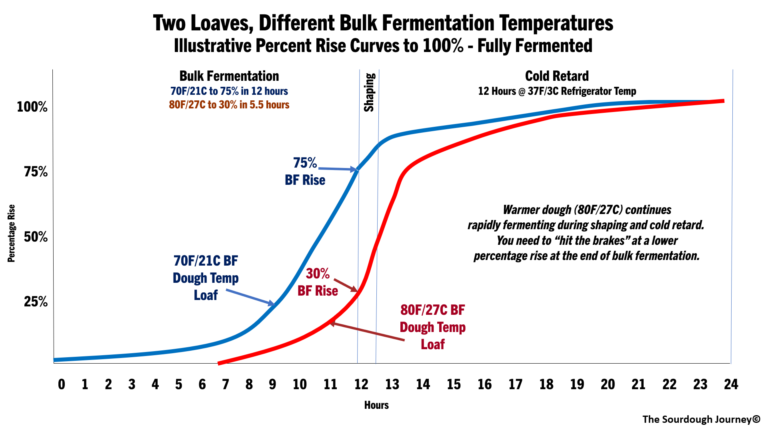

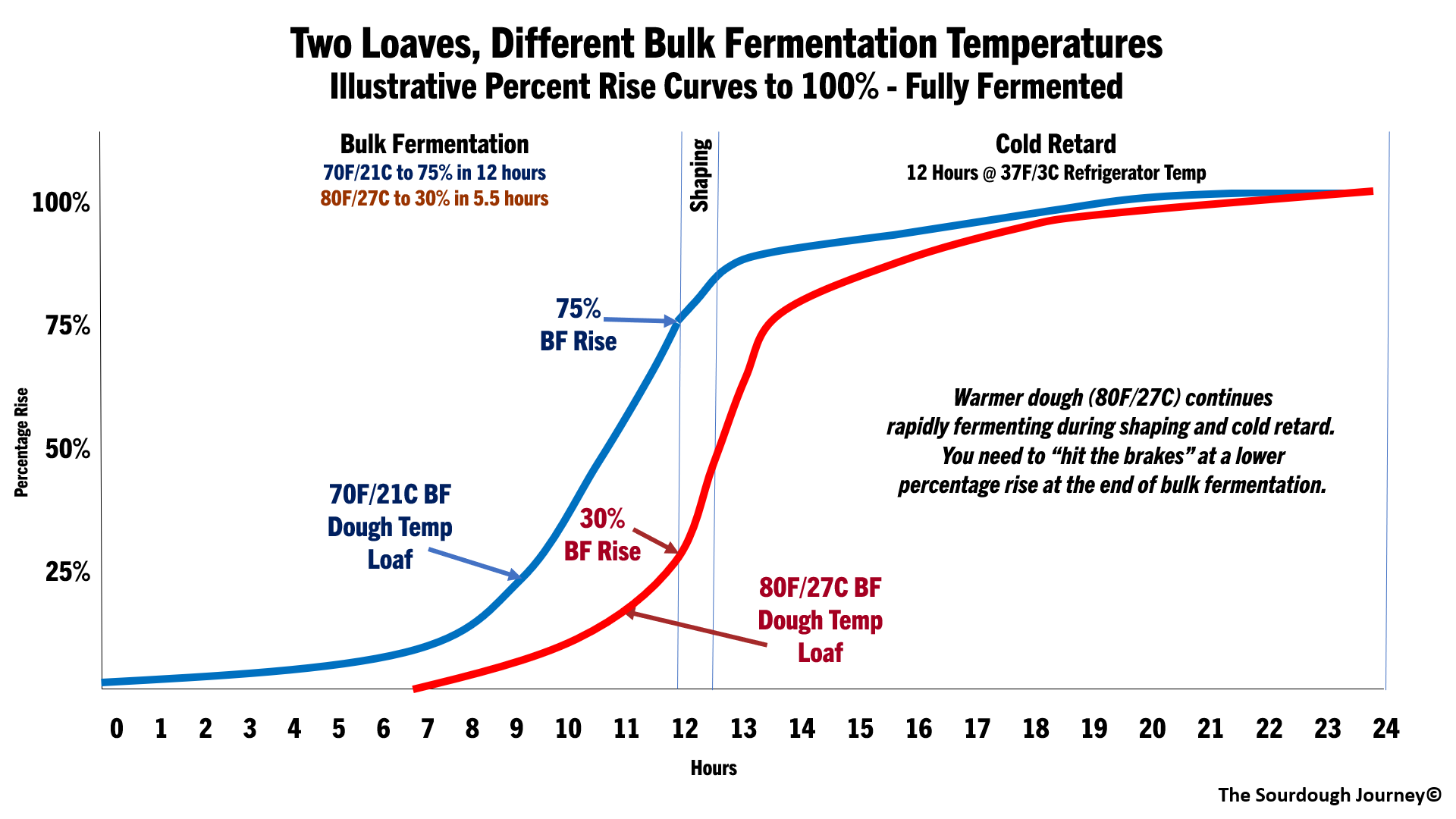

PART 5: FERMENTATION CURVES AT DIFFERENT TEMPERATURES – AN ILLUSTRATIVE EXAMPLE

Based on the information in the prior sections, we can construct an illustrative fermentation curve for 80F/27C dough and 70F/21C dough throughout the entire fermentation cycle. In this example, assume that all dough needs to theoretically rise to 100% to be fully fermented. We know that we cannot visibly measure the percentage rise through the shaping steps, because of degassing, or in the refrigerator because the gasses shrink at cool temperatures. But if you imagine you could accurately measure the percentage rise throughout the process, this is what the percentage rise curves would look like over a 24-hour cycle.

Cool Bulk Fermentation – 70F/21C Dough: Target Bulk Rise 75%

Cool Bulk Fermentation – 70F/21C Dough: Target Bulk Rise 75%

A loaf bulk fermenting at 70F/21C may take 12 hours to reach a target rise of 75%. At the 75% rise, the dough is shaped, where it rises 5% more to approximately 80%. The dough then goes into the refrigerator where its rise curve flattens fairly quickly and it slowly rises to 100% over the next 12 hours.

Warm Bulk Fermentation 80F/27C Dough: Target Bulk Rise 30%

A loaf bulk fermenting at 80F/27C ferments much more quickly. It reaches its 30% target rise in 5.5. hours of bulk fermentation. During the shaping process it rises another 10%. Within the first few hours in the refrigerator, it has risen to 75% – the same point where the cool loaf exited bulk fermentation. In the final few hours of the cold retard, both fermentation curves converge, and the loaves end up at exactly the same level of fermentation.

Cool dough requires a higher rise in bulk fermentation (75%) because it cools down and slows down quickly as it enters the refrigerator. Warm dough starts faster and maintains a warmer temperature in the refrigerator. It continues its very vigorous fermentation rate for a few hours in the refrigerator.

FREQUENTLY ASKED QUESTIONS

What is the best temperature for bulk fermentation?

You can bulk ferment at virtually any temperature between 50-90F / 10-32C. The key is to synchronize the target percentage rise with your dough temperature. Warm dough requires a low bulk rise and cool dough requires a higher bulk rise.

Why don’t I see the dough rising in the refrigerator?

As your dough cools down in the refrigerator, the carbon dioxide gasses that inflate the loaf begin to shrink at low temperatures. So the dough is still “rising” but it is shrinking at the same time. Once the loaf warms up in the oven during baking, the cool gasses expand and produce some of the explosive ovenspring that you see in the first 20 minutes of baking.

Is the target bulk fermentation temperature the “ending temperature?”

No. It is the average (and ending) temperature. Bulk fermenting your dough is not like cooking a steak where you are trying to raise the temperature to a desired end point. Bulk fermentation works best if you can maintain your target temperature throughout bulk fermentation. Use tools such as a desired dough temperature calculator and a proofing chamber to maintain a constant dough temperature throughout bulk fermentation. Temperature fluctuations during bulk fermentation can result in uneven dough fermentation with some parts of the dough fermenting faster or slower than others.

The appropriate target percentage rise is more influenced by the ending dough temperature because that temperature influences the fermentation in the downstream steps. Bulk fermentation times generally are driven by the average dough temperature during bulk fermentation.

How do you accurately measure the percentage rise?

Use a vessel with milliliter markers on it. Your starting point is the volume in milliliters after you have mixed all of your ingredients. Sometimes the dough is domed on top after mixing and it is difficult to get a good starting measurement. For most country loaf recipes (e.g., Tartine at 75% hydration and 20% starter), the initial starting volume of the dough is equal to 1.5x the flour weight in grams. For example, a 500g flour-weight recipe typically mixes up to 750 milliliters of initial dough volume. You would then multiply this number times 1 plus the target percentage rise to mark your final volume target. For example, a 50% target rise would be 750 milliliters x 1.5 = 1,125 milliliters.

Many recipes call for the dough to double in volume and don’t specify the target dough temperature?

I don’t recommend following those recipes.

How can I learn more about this topic?

I have dozens of videos on my YouTube channel at The Sourdough Journey on this topic. Here is a good place to start. When is Bulk Fermentation Done?: Episode 8 – Low and Slow.

You can also find more information on this topic at thesourdoughjourney.com

If you find the information helpful, please support The Sourdough Journey at thesourdoughjourney.com/donate

Appendix 1: What Happens in the Oven During Baking

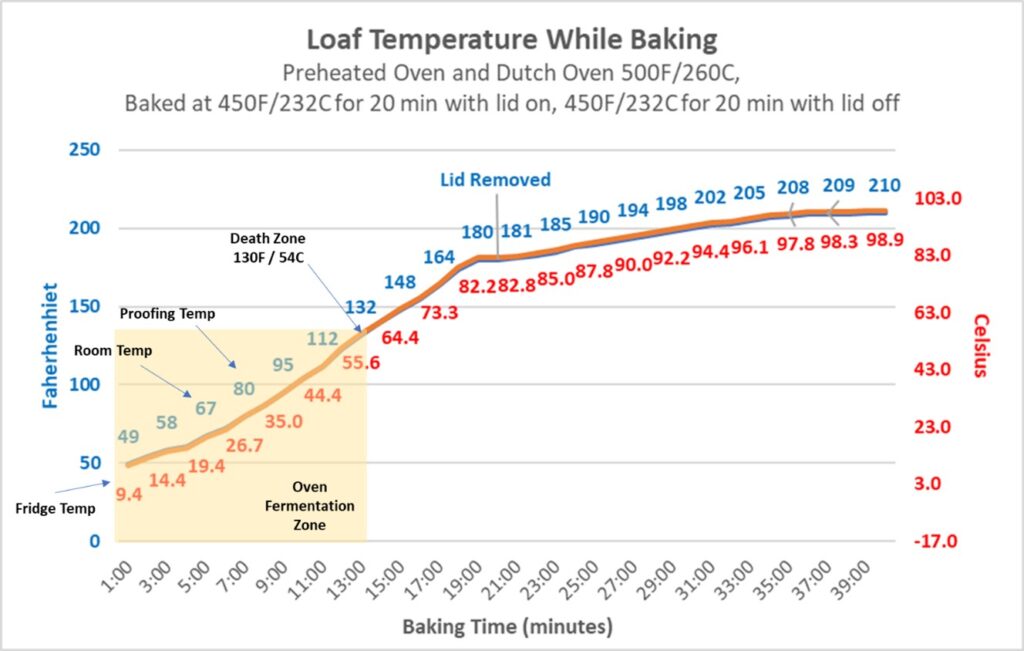

Once your loaves reach the oven, after a cold retard, there is still one last stage of fermentation that occurs in the oven. As your cold dough warms up in the oven, the yeast and lactic acid bacteria reactivate for a short, but powerful, “last gasp” of fermentation until the dough reaches the 130F/54C die-off temperature.

In a typical bake where a cold loaf is loaded into a preheated oven and Dutch oven, the dough will rise to active fermentation temperature (70F/21C) in about 5 minutes and will continue very rapidly fermenting and producing CO2 for about 15 minutes until the dough temperature reaches 130F/54C. At that point, all fermentation finally stops.

For more information on this topic, check out the video, “The Secrets of Ovenspring and Baking Temperature.”

Tom Cucuzza

Share:

Related Posts

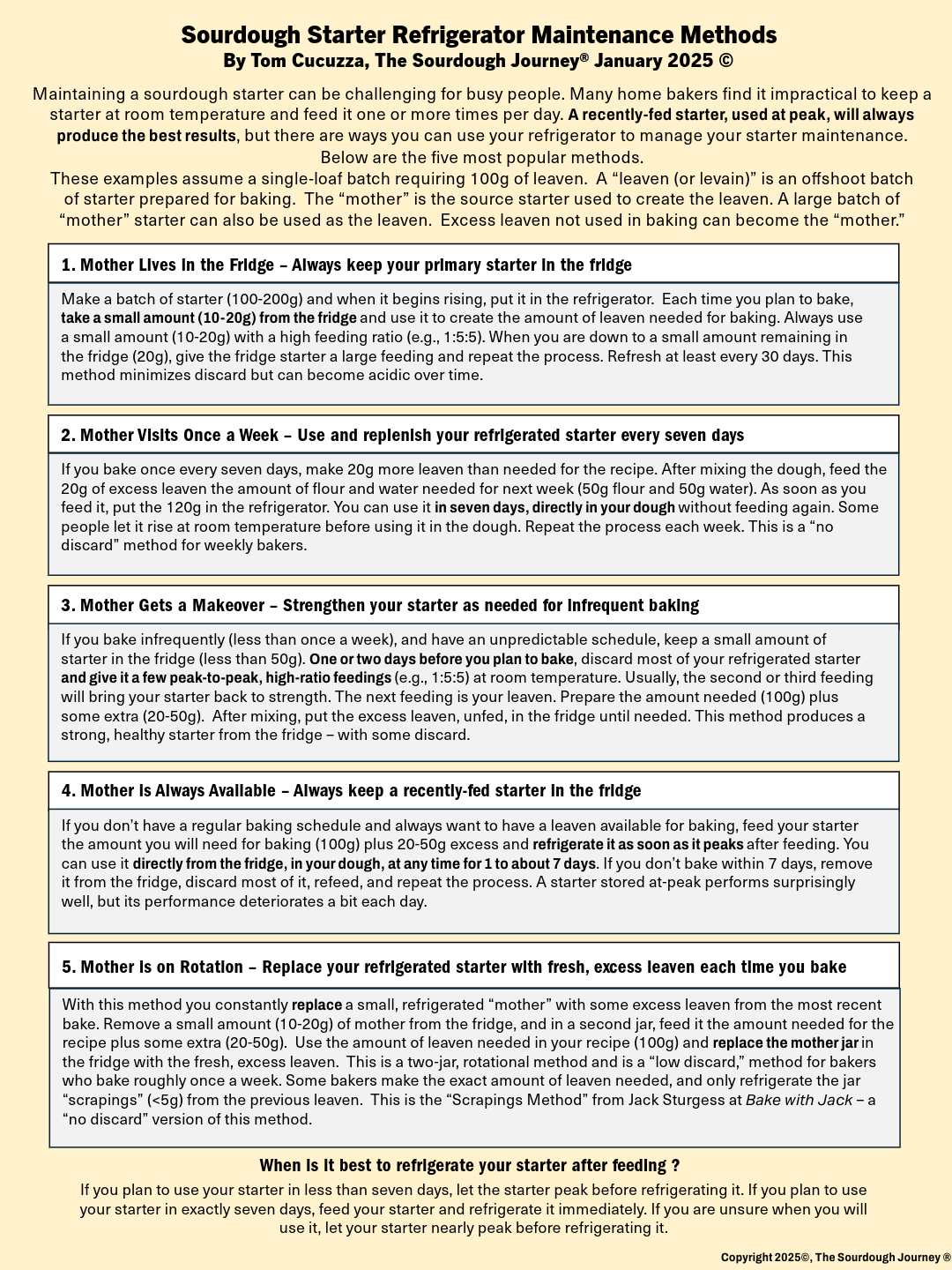

Sourdough Starter: Refrigeration Maintenance Methods

How can I maintain my sourdough starter in the refrigerator instead of at room temperature?

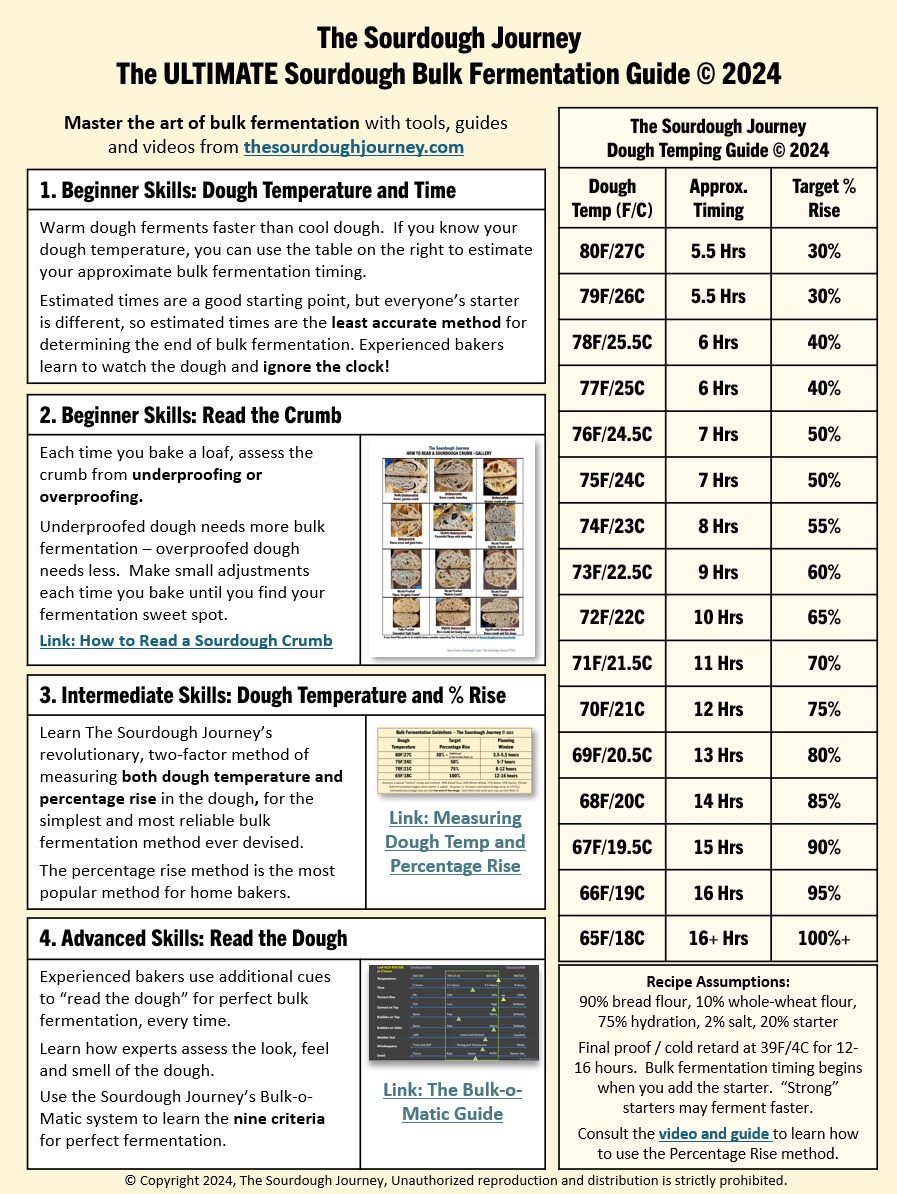

The ULTIMATE Sourdough Bulk Fermentation Guide

When is sourdough bulk fermentation finished?

Dough Temping for PERFECT Sourdough Fermentation

What is sourdough “dough temping,” and how does it work?

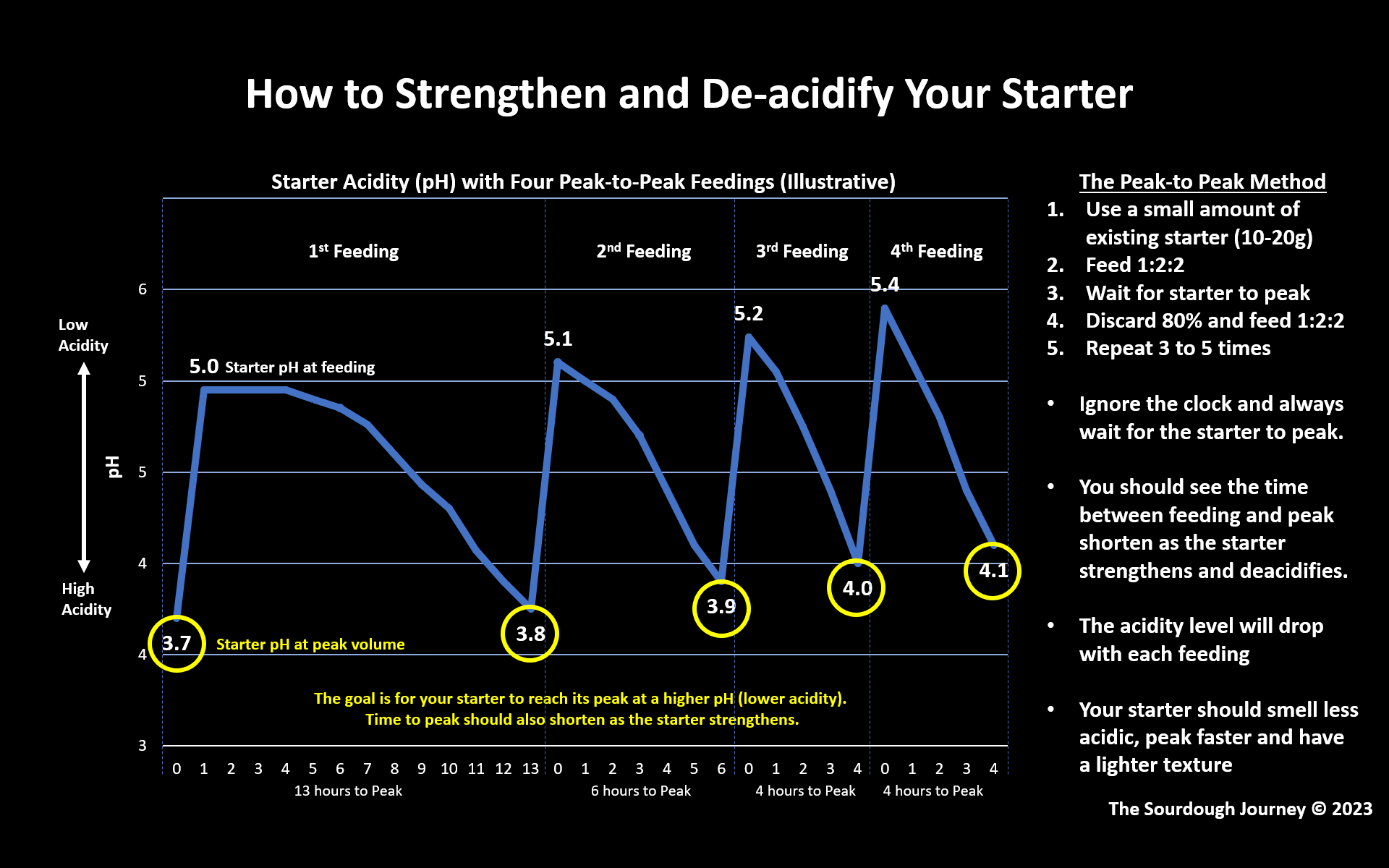

The Science of the Peak-to-Peak Method of Strengthening a Sourdough Starter

What is the Peak-to-Peak Method and how does it strengthen a weak sourdough starter?

How to Strengthen a Weak, Acidic Starter

Is your sourdough starter sluggish? How do you identify and fix a weak, acidic starter. This document is the companion guide to the popular video “How to Strengthen a Weak, Acidic Starter.”